Summary

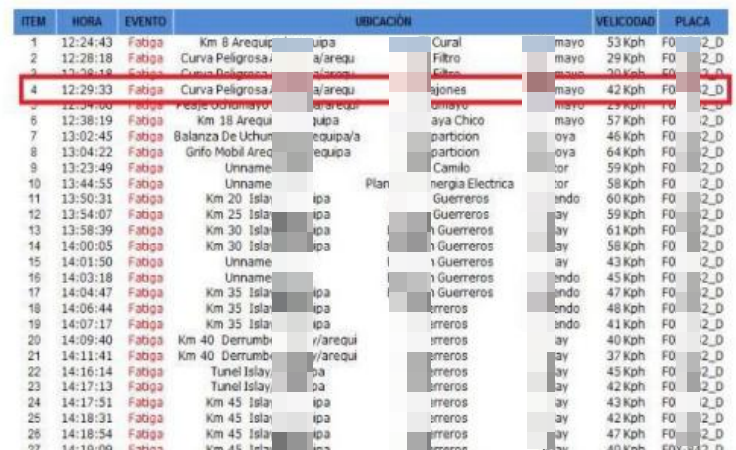

When the system detects driver fatigue or distracted driving, the driver's cabin will trigger a sound alarm and seat vibration simultaneously. At the same time, the alarm signal, positioning data and driver status pictures will be uploaded to the management backend to assist managers in formulating targeted safety strategies and significantly reduce the accident rate.